When Michael Thomas Clarke restructured Bakrie Construction about two years ago, he traveled to Japan and visited the country's leading power companies. " In Japan i saw the potential that we were looking for, wich was the production of modular fabrication for their industrial development overseas, specifically for power stations, say the president and CEO. The trip proved profitable because he secure a project spearheaded by Mitsubishi Heavy Industries to fabricate 3,000 tons of equipment for the recirculation pipng systems of a power plant in Indonesia.

Established in 1985, Bakrie Construction operates a 17.2 hectare heavy industrial steel fabrication yard with capabilities to construct large modular equipment ranging in size from 500 to 2,500 tons.

The yard includes a bonded zone area with registered IPSA harbor facilities that enable the company to receive materials or directly export fully integrated steel structures and modules to Asia and other overseas market.

Bakrie's reputation in the steel fabrication and construction industry has been outstanding over the last 30 years. But since restructuring two years ago, it has increased its international focus and raised the quality of production worldwide.

"There were several areas to refocus the company's direction. We upgraded safety, quality and management systems in the company to take on the challenge of further promoting the international business, say Clarke."

Given the companys global focus, Clarke sees opportunities in partnering with the Japanese not just in Indonesia, where it has been operating for 25 years, but also overseas.

"There are indeed international projects where Japan builds power plants and we know we can comppetitively supply them with the needed equipment," he says.

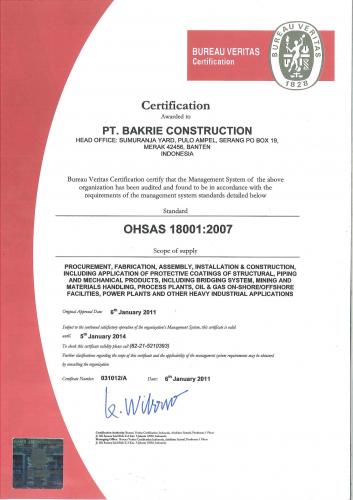

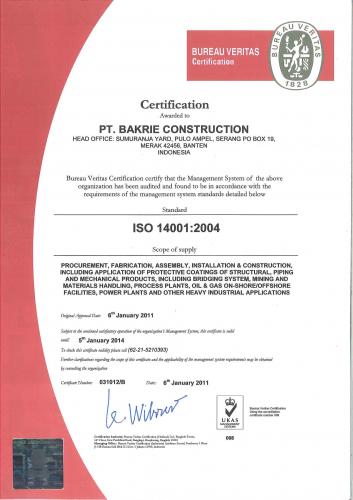

The Company takes pride in its proven track record as a world class contractor, and has all needed accreditations required by the Japanese and other international companies.

The Company takes pride in its proven track record as a world class contractor, and has all needed accreditations required by the Japanese and other international companies.

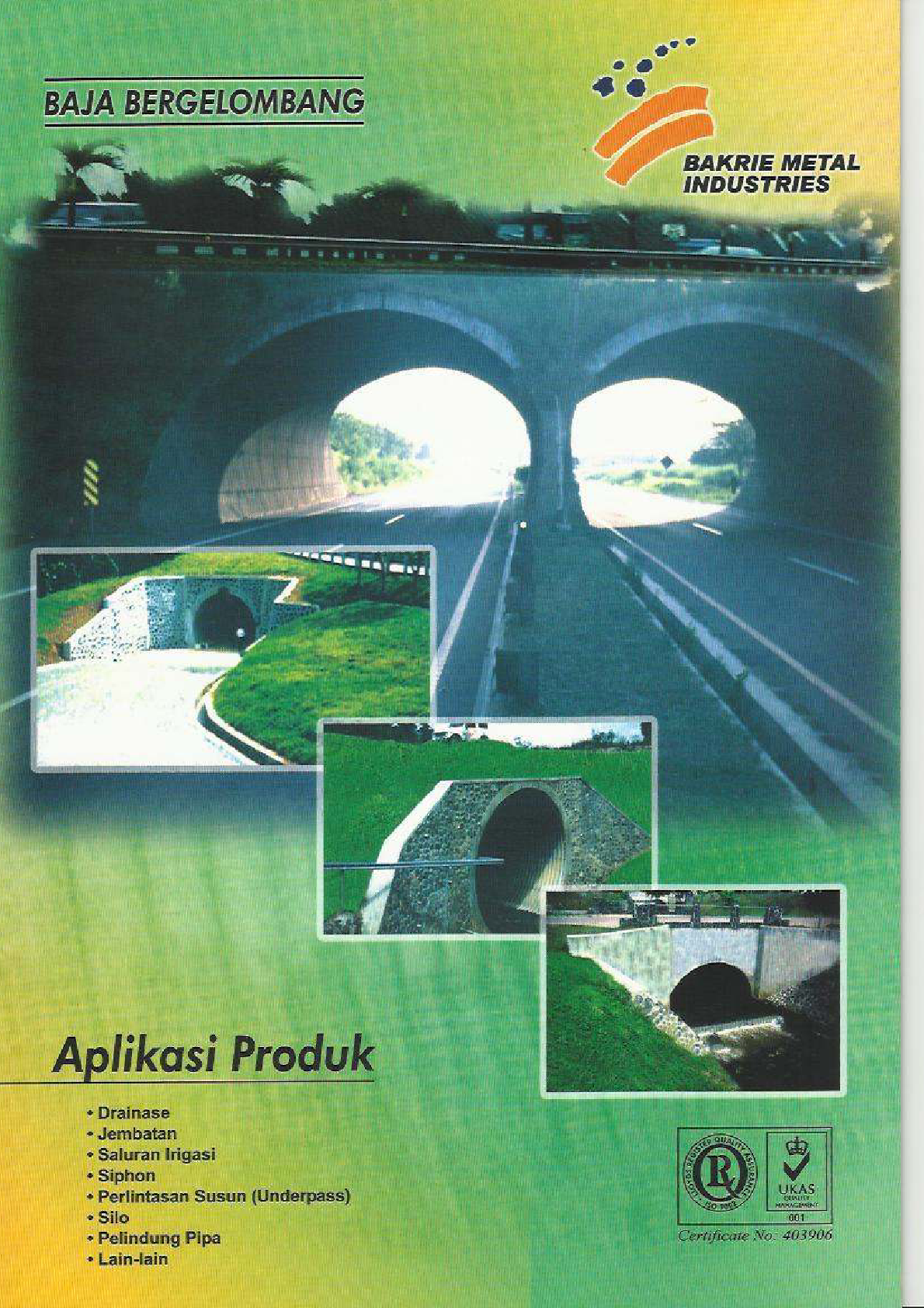

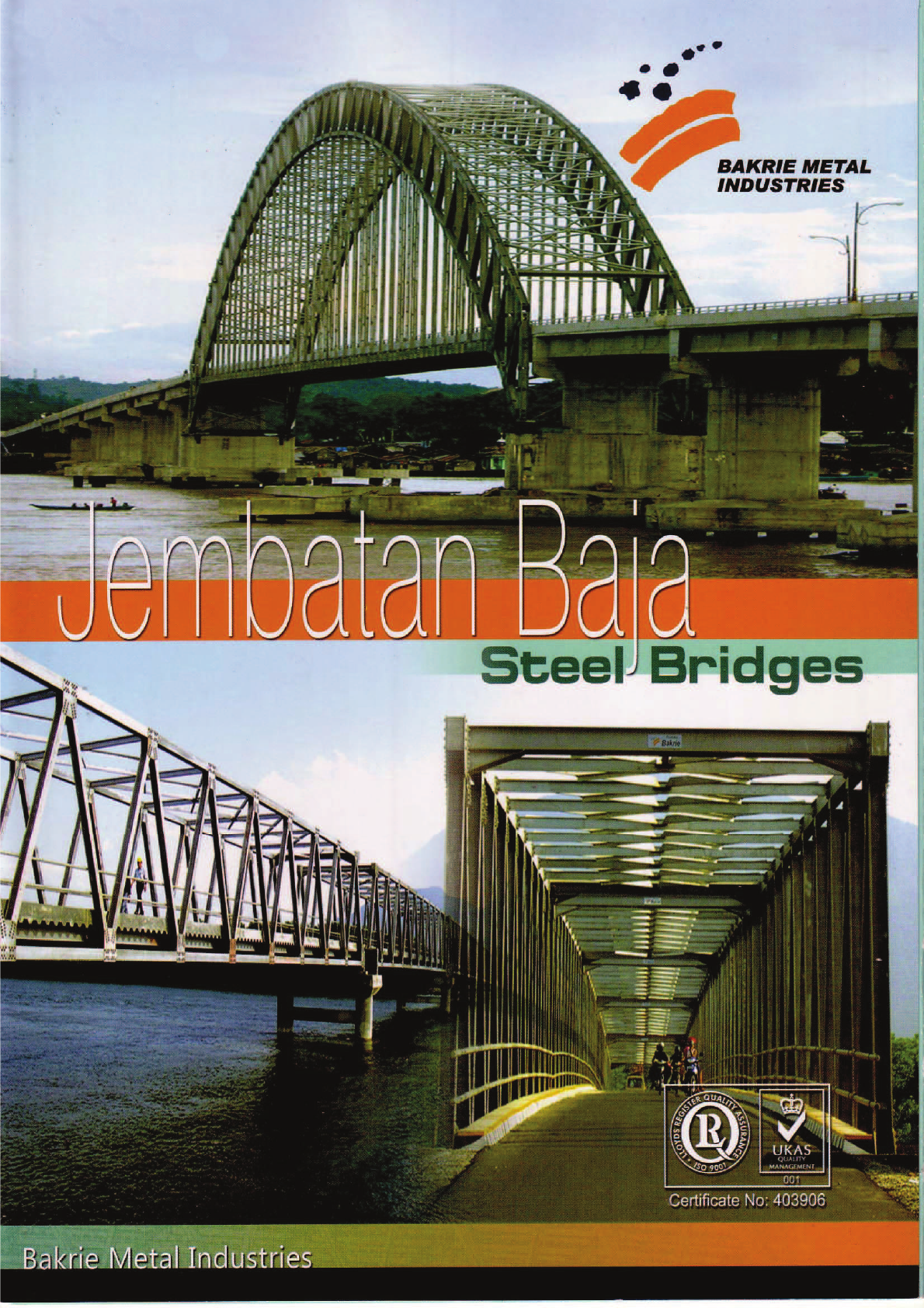

"Our particular focus in supplying high class fabrication product to Japanese companies and meeting all international standards for construction, quality and safety. That's where we are. We complete with those standard and competitively so. We have a great care for our customers. We want them to come back the next time and we know the Japanese are very responsive to that he explains. Apart from the company's core business of fabrication and construction of modular equipment for the oil and gas, power, mining, marine and infrastructure industries, it also look into further diversification as an EPC Contractor, offshore services contractor and pressure vessel fabricator.

Source: World Eye Reports